"Strapless" mechanism with posts soldered directly to flute body. |

William Winthrop

Haynes

|

"Ball" shaped adjusters on WW Haynes #365 flute above are similar to original Boehm design..  "Cylinder" shaped adjusters on WS Haynes #6984 (1922) commercial model. |

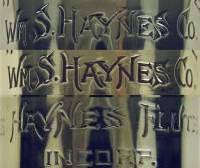

Barrel engraving of William Winthrop Haynes flute could easily be mistaken for one of his father's instruments. |

After much

legal wrangling, in 1920 the son had incorporated his firm to form "The

Haynes

Flute Company, Incorp." -- with engraving almost identical to his

dad's. He even went so far as to change his legal name to William

S. Haynes, Jr. -- one can only speculate that this might have been less

a business stratagem than a backhanded compliment. The courts ruled in favor of the father and, in July 1921, the younger company's name was changed again to "The Haynes-Schwelm Co." (John Schwelm came from the father's shop, a few years later leaving the son as well to eventually become foreman at Powell's shop.) |

Note the similarity even in the engraving style. The top two come from 1922 and 1923 commercial Wm. S. Haynes flutes, the bottom from this W. W. Haynes flute. |

|

This flute

appears to have been made during the brief period of

1920-1921. Not surprisingly, keywork is very

similar to flutes from the father's shop. The son's R1 shake pictured on the left shows a bit more "robust" work with angled key arm and less finish than the more fluid keywork of the 1923 (#7458) flute from his father's shop just below. At the right is a comparison of footjoints, with this flute pictured above a 1922 WSH footjoint. The C# key arm is simply notched to accommodate the C roller in the son's flute (top), while the same key arm in the father's flute (below) is more delicate in its sweeping curve below the C roller. The father's flute also shows more of the older style "teardrop" D# touch (and a better reflection of my hand holding the camera). The toneholes are drawn but not rolled. This is not so much a problem as it could be on some flutes -- the edges that contact the pads are not very sharp since the flute body is quite as thick as any I've run across at .021". This also provides a solid base for the strapless mechanism, with key posts soldered directly to the tube body. |

|

Images © J. W. Sallenger